Tehla, Rajasthan

In a village called Tehla near Jaipur, crushed lime waste ‘Bagra’ is extensively used for mortars, plasters as well as making flat lime roofs. These exemplify the beauty, strength and possibilities that lie within a natural material like lime. While the extravagant palaces of Jaipur used lime copiously, these humble homes took the leftovers of the lime waste using it efficiently. Indeed nothing goes to waste in our villages that making the best use of the available resources. Not only is this economical & ecological it is also a sensible approach towards the natural building.

These roofs existed centuries before even the concept of a reinforced concrete slab was born. This is our very own indigenous stone reinforced lime roof which is much more durable and lasts so much longer. What’s more, it doesn’t heat up your home, regulates the temperature and most importantly lets your home breathe, especially if you’re in a hot and dry region like Rajasthan. The bagra is ground in a chakka, and natural strength imparting additives are added to the mix. Fenugreek seeds soaked in water, guggal (commiphora mukul), jaggery, etc are added to this impart desirable qualities of strength and setting time in lime. These are the original admixtures of ancient times.

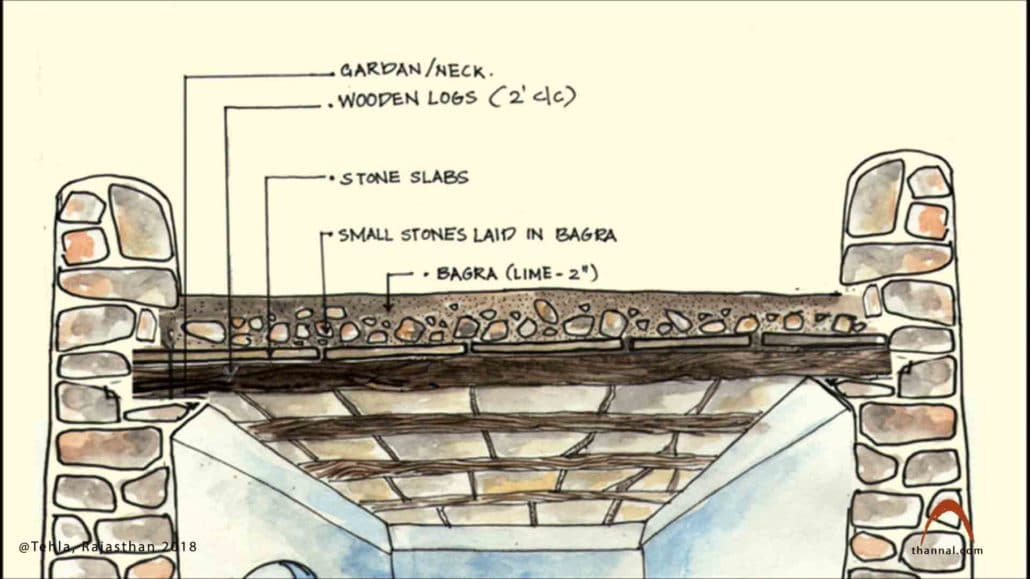

The above photo clearly shows a broken Bagra roof with the details of the flat roof construction. The beauty in ruins is that it reveals the materials layer by layer exposing the real structure, helping us understand, almost witness the process of building it. Below is a deconstruction of the layers of the lime roof.

- Wooden logs are used as spanning members with 2’ c/c, which act as the base for the roof. These rest on the stone wall projections called ‘gardan’, literally meaning neck. These spanning members can either be wood or stone slabs (pink sandstones).

- The next layer is that of big stone slabs laid with bagra mortar to cover the gaps between the wooden members.

- Above this, smaller stones with larger quantities of bagra are laid further filling the gaps between the joints making them impermeable.

- The final finish is a layer of bagra which is almost 2” thick. When this hardens we have a waterproof leakproof flat lime floor.

- Two stones slabs project out of the parapet act as the rainwater drain, with the slope of the roof towards the drain.

Though now it is difficult to attain the workmanship and retain the materials once used, to exactly replicate to obtain similar results, it is worth to try and experiment from learnings of the past while applying knowledge through our own experiences and research. This is a ray of hope and inspiration for natural builders to look at application of lime waste in in flooring, foundation, lime bricks, etc. as natural building components. Curiosity will lead us to stumble upon new discoveries and rediscoveries in building naturally, to help ourselves and others in this process of creating a habitable shade without a trace of cement and steel.

Musharaff Hebballi

This article is by Natural builder Musharaff Hebballi. This post is part of our Natural Finishes series,.

4 thoughts on “Bagra flat lime roofs”

Namaste Indrajit,

Kindly write to thannalroots<@>gmail.com

Hi,

I have a gable slope roof made of galvanised steel sheet covered with 4 inches of concrete. Waterproof treatment has also been done. I want to further apply hydrated lime for keeping the upper rooms cool. Is there any way to do it?

Thanks

Namaste Suresh,

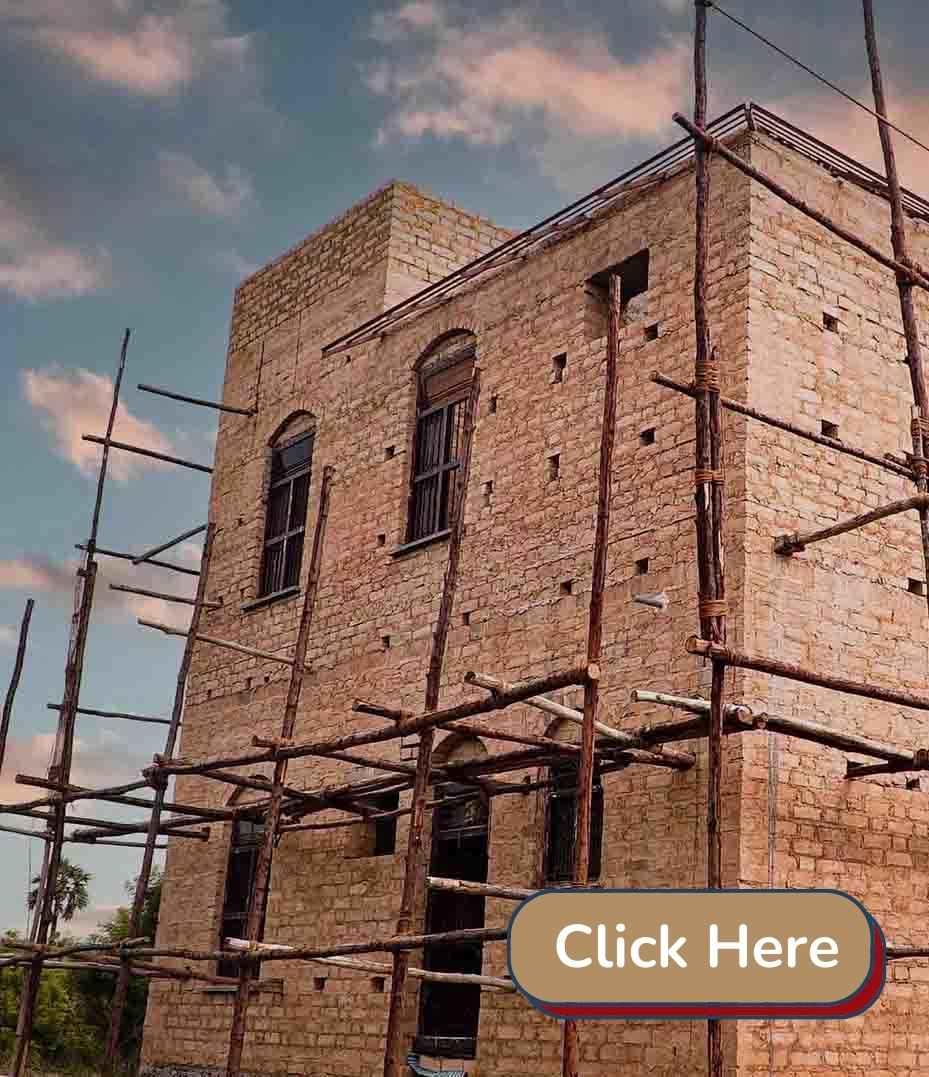

Yes, it is indeed possible to use this construction methods, such as those employed in natural building, as alternatives to conventional load-bearing RCC slabs.

Regarding the construction of G+2 or G+3 buildings using these methods, it is feasible.

You can read more about other methods here – 8 Flat Roofing Techniques For Natural Buildings You Need To Know

Is it possible, to use this method as an alternative to the conventional load bearing RCC slab…?

Can we build G+2 or G+3 buildings using this method?