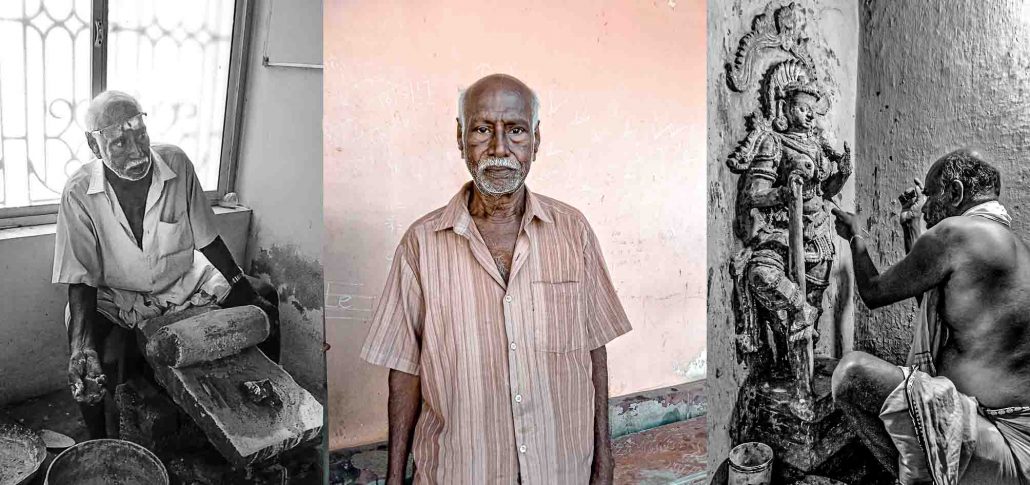

Respecting an artisan series with Master artisan, Nataraja Pillai ayya

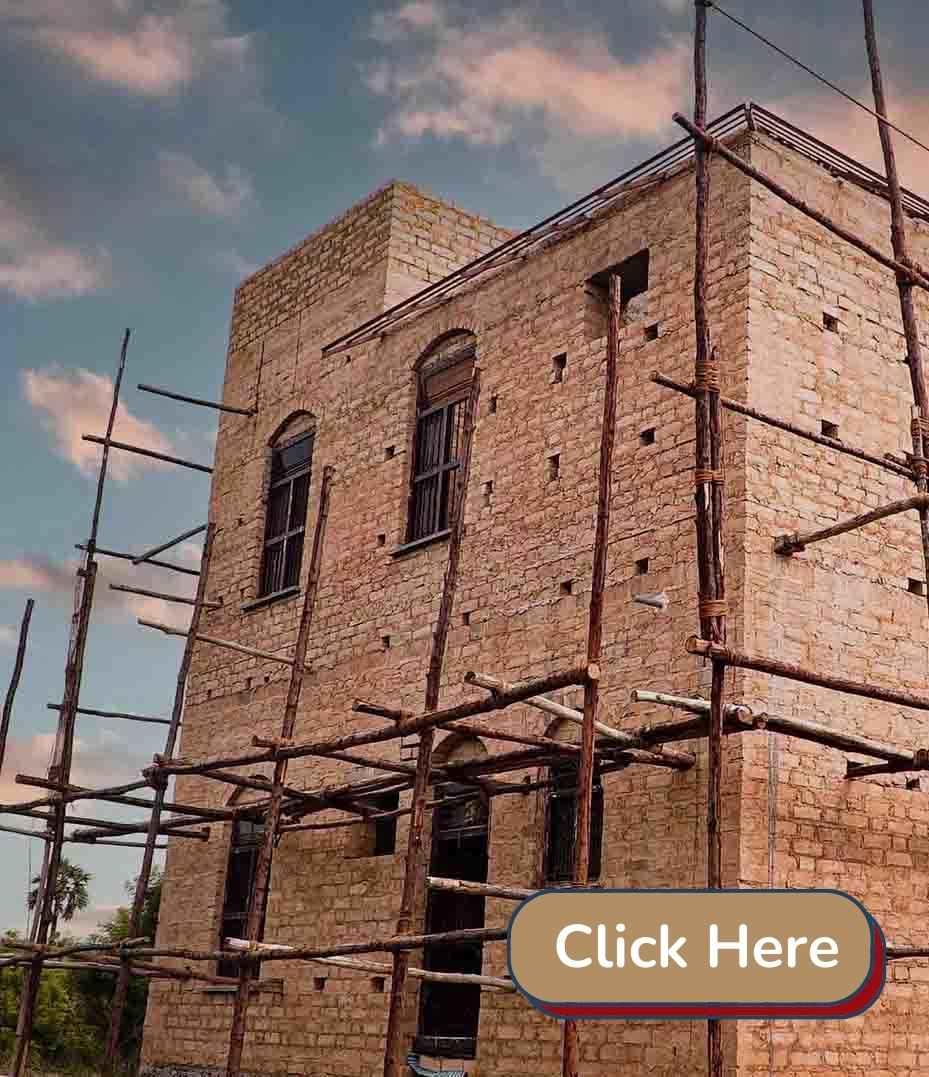

The journey to explore the traditional natural building techniques behind the double-storeyed mud structures of Nagercoil traced to an old artisan, who could unveil it all. To know the natural building techniques belonging to the region, check out Natural building techniques: Cob Foundation and Flat Adobe roof using Marine algae – Nagercoil.

Nataraja Pillai ayya, an 82-year-old Stapathi and temple Architect in Nagercoil, is still actively involved in designing and executing temple constructions in the region, restoration and rehabilitation of old temples and statues. He was a mason in his early life, closely working with the natural materials and understanding them deeply.

Here, is a compilation of the interview with Nataraja Pillai ayya, on the usage of lime, lime plasters and various mud plasters that were practised in the region of Nagercoil.

How long have been working with natural materials?

My forefathers have all been associated with natural materials and, have worked on several houses and temples. Then, I and my brothers have all emerged into different branches of the same path. I have been involved in construction and working with natural materials from a very early age. My path later diverted mainstream into sculpting and temple architecture, when I could get my hands more on stone, brick and lime.

What was the usage of lime in construction traditionally, in this region?

Initially, years back, communities that were economically weaker had their houses built just out of the mud and, those structures barely had lime in them. Lime, which is now seen as a primary material without which a natural building is impossible, had always been seen as a luxury added to the material palette of a building, in very early times! Techniques involving lime started to flourish in a later period after the start of wide usage of burnt bricks until which, lime was a constituent only in the houses of the rich. But in a later period, lime was started to be employed in mortars, plastering, foundation and flooring.

How is the lime mortar prepared and used?

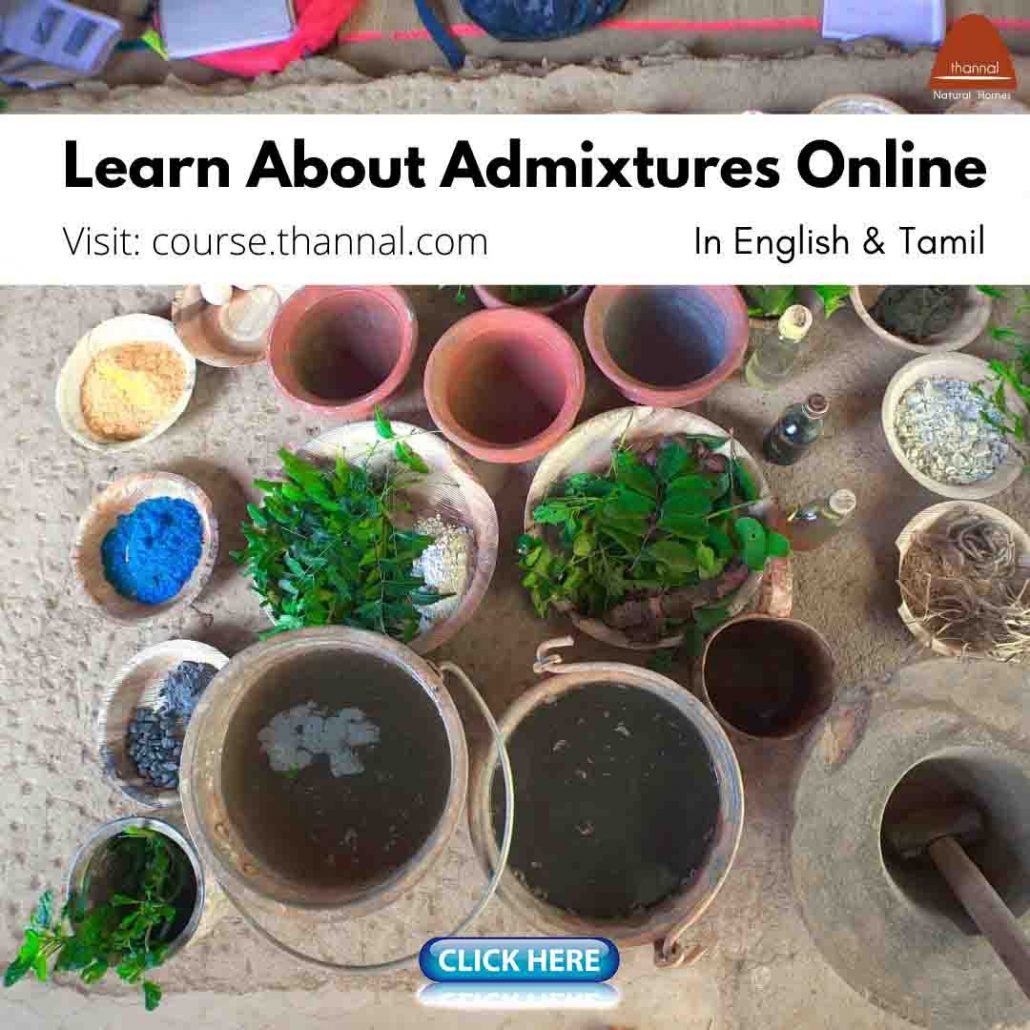

Masonries like stone and burnt bricks require a similarly hard mortar and that’s when, a lime mortar comes into play. It is a combination of lime and sand mixed together along with the admixtures and, grinded in a grinding chakk.

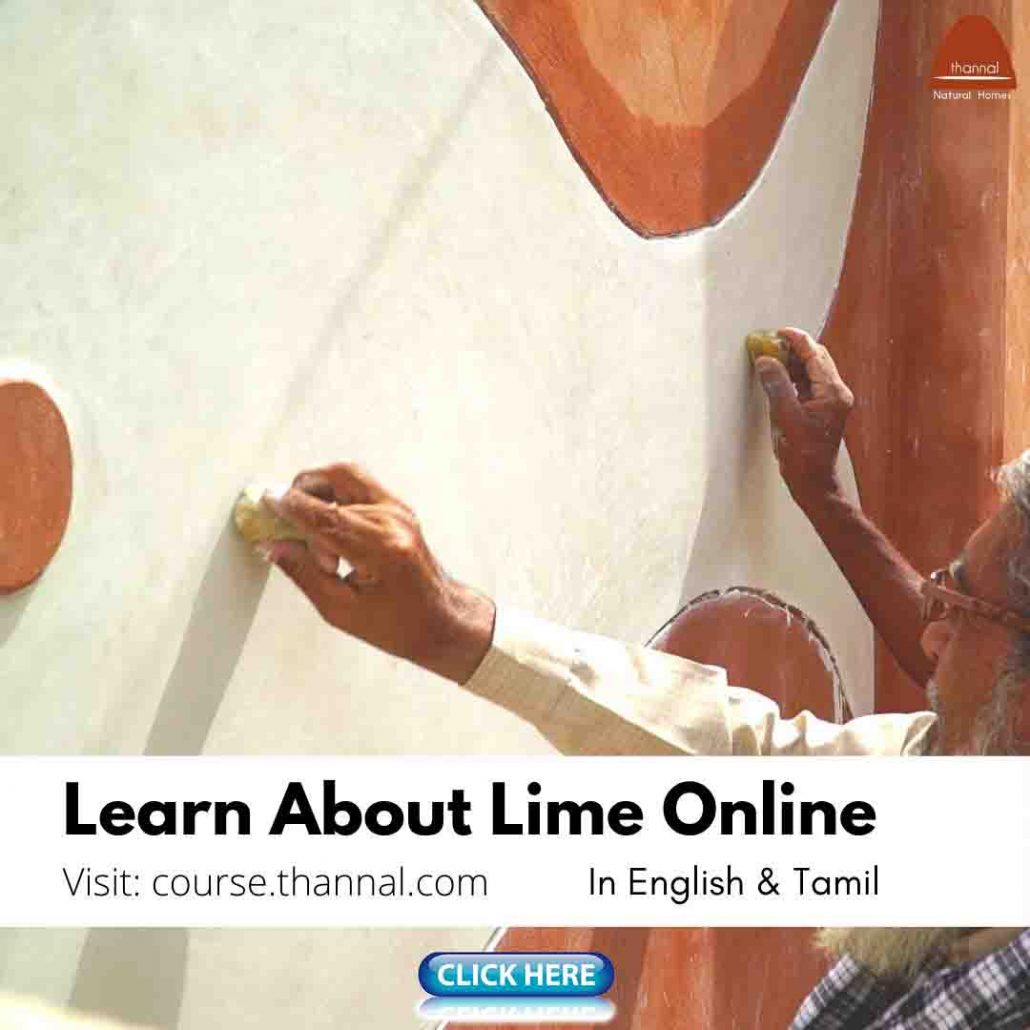

What is lime sand plaster? What are the benefits of it?

The huge spans of exposed mud walls that you see standing tough, says it all! Try breaking a small chunk of the plaster from one of these old walls, and you’ll know how strong lime can become with time! Lime sand plaster is a combination of lime and sand with a more concentrated quantity of lime. After mixing them along with the admixtures, it is grinded, let to ferment and used. Being a strong plaster, it is mostly preferred for exterior plastering. It is usually done in two coats.

Which type of lime(stone/shell) is usually preferred for lime plaster?

Shell lime, due to its ease of availability in this region, was used for almost every part of the construction including plastering. But otherwise, both shell lime and stone lime with good lime content in them can be used.

How important is the grinding of lime plaster?

The strength of the lime plaster relies on how well the grinding is done! Grinding of the plaster is essential to crush the unslaked portions of lime if any and to create an intimate mixture so that no two grains of sand are without an intermediate film of the hydrated lime. Grinding also leads to a reduction in the particle size of the sand, thereby making the plaster finer.

What are the various Mud plaster finishes that prevailed in the region?

Before the lime plasters, more than a few centuries ago, mud plasters were the most commonly prevailed finishes for mud walls. One of the simplest mud plaster mixes includes any clayey soil available and sand in equal parts. Kummayam is a mud lime plaster made out of equal parts of lime, sand and red soil. There were several other mud plaster combinations also, depending on the availability and the type of soil in the region.

How do mud plasters perform when exposed?

Mud plasters have always been used on external wall surfaces. Though lime is an excellent stabilizer of soil and provides immense strength to the building, it was not used in all houses. Our ancestors believed that a similar strength can always be achieved with the right usage of several plants and animal admixtures along with the mud! Or, coats of limewash over the mud-plastered wall can also work well on the exposed walls.

What is the importance of limewash?

Limewash is a thin coat of slaked lime putty. It is applied as a final layer on the plastered walls, to provide additional waterproofing. It was traditionally reapplied every year during Sankranti as a part of the festival rituals, thereby a frequent periodical lime touchup is given to the walls, increasing the waterproofing.

How is waterproofing achieved elsewhere in a building?

All the surfaces exposed to water, be it the flooring, open terrace, courtyards, walls or flat roofs, were rendered with the same formula of lime sand plaster mixture, along with lime wash. The waterproofing is achieved more and more with time and, increasing the number of lime washes, thereby letting the exposed areas stand tough amidst the harsh weather.

How do you see earthen structures amidst the modern building typology?

I’ve worked on several houses in the region that are now nearly 50 to 60 years old. I have also seen a lot of houses that are more than a century old, out of which a few are still standing tough. Meanwhile, a lot of them have been demolished and replaced with modern houses. Standing as a testimony to its timelessness, an earthen structure purely out of nature, surrendered under the feet of mother earth, serves mankind for longer and longer. And for it, all that is expected is nothing more than patience and a constant human touch to it!

What is the impact of modernization on temple architecture?

Modernization has not even left the temples free. In the earlier times, statues were made out of mud and lime, giving a good wooden framework and supports. Mud and lime mixtures needed, were specially prepared in a certain way, like it was done for construction. It demanded a lot of hard work and patience. The statues that are piously seen as a place where the God resides, seemed more sacred this way. Now, the statues of god are being made out of bricks, cement and steel reinforcements. And, temple gopurams once constructed out of stones, bricks and lime are now being replaced by bricks and cement.

So, the ultimate moral we realize is that the current generations have started considering what humans fabricated to be supreme over what nature has provided. Time will answer it all and eventually make mankind realize!

Ramani Rajam

This article is by Natural builder Ramani Rajam. This post is part of our People & Interviews series,.

4 thoughts on “Interview: 82 years old Tamil Nadu sthapathi (Master artisan) Nataraja Pillai ayya”

Thanks Suren

Namaste Partha, Nice to know that you like the interview

Salute to master artisan ,thanks to interviewer. Lime based knowledge developed over the centuries is our ancestors property and we must take care of it.

Good work Ramani. Happy to see such young people like you are serious and passionate about the traditional and ancient methods of construction. You are definitely going to make difference in future.