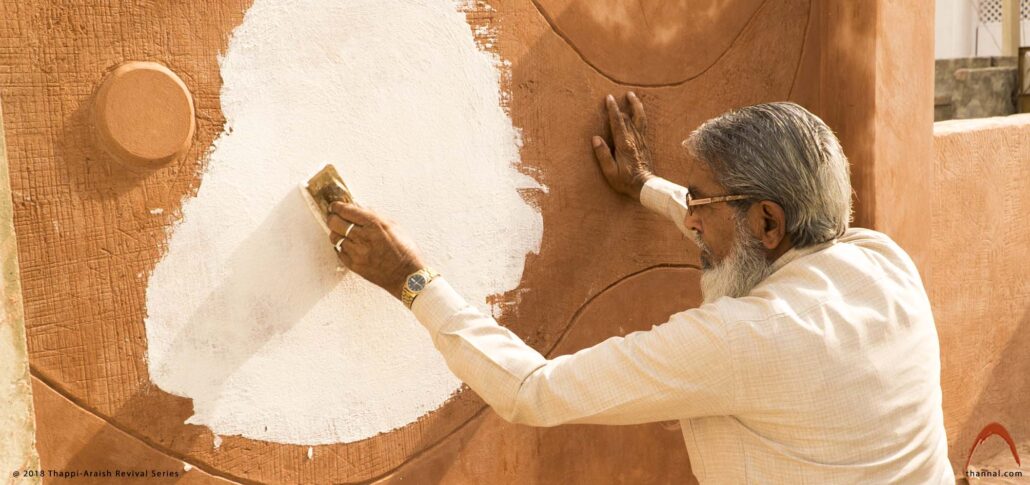

(Revival Series: Thappi-Araish Lime Plaster, Rajasthan)

Abdul Razak Muwal (known as Bhauji Mistiry) from Sardarshaher, Rajasthan is a master mason and lime artisan. He belongs to a family of lime extractors and farmers. Being the eldest son of the family, he started working at an age of seven under Abdul Painter ji, his wife’s grandfather, who is famous in Sardarshaher for many Haveli (mansions) and Ghanta ghar (Clock tower). Later he become a mason and did many projects in Sardarshaher, Jaipur and Goa. He was actively part of many conservation projects in Mumbai (Gol Dev Mandir in Bhindi Bazar) with prominent architects. He is the elder brother of Dawood Ibrahim Muwal and was actively part of our Revival Workshop of Thappi Araish Plaster held in Sardarshaher in May 2018. At the age of 68, he is a senior member of the Lime Artisan Community who is still in practice. After a series of dialogues and in-deep discussions with Biju Bhaskar on Lime, a few simple questions and answers about ‘Thappi-Plaster’ by Bhauji Mistiry is compiled below.

1. What is Thappi Plaster?

Thappi is a wooden tool used to beat Chuna (lime) & Surkhi (burnt mud) in plaster so that both will blend together and become one. It is essential that Chuna and Surkhi become one so that they will not flake off or crack and fall off. After Thappi is applied, there will be no seepage of water as there are very little or no cracks. Thappi also makes a single unified layer of lime and Surkhi, which makes it difficult for the water to penetrate. Just as how ironing of cloth makes it hard and stiff, Thappi makes the plaster layer intact by pressing different layers into each other. Thappi is given until a ringing sound is produced upon beating by the Thappi tool, indicating the lime has dried and started settling down.

The beating of lime with various tools has been found traditionally in different parts of India. Giving Thappi over the surface when the lime is freshly applied and is yet to dry, will push out the milk of lime from the surface. This makes the lime go further inside and bond strongly with the base and a very compact layer of plaster is achieved.

2. What are the major types of Chuna (lime) you have seen or worked with?

Simla Chuna, Meetha Chuna, Darbari Chuna, Kali, Kalar Chuna are the different types of stone limes available in Rajasthan.

Many different kinds of limestones are found naturally in the ground. The stones which are full ‘pakka’ (strong) from inside are used for ‘chinai’ (masonry) as building units. Limestones that are porous, have jaali (cavities) inside are used to extract lime.

Kacchi Bhatti and Pakki Bhatti are two different types of kilns in which limestone is burned. Kachha Bhatti uses ‘gobari’ (dung cakes) for burning. It is burnt in the open, without enclosing or covering, so the effective temperature of burning is less. Burning time is also less (overnight) and lime is taken into use the next day. Pakki Bhatti uses wood or charcoal for burning. It is an enclosed burning where the kiln is generally made of mud. It is burnt for a longer duration and takes a few days to cool down. Effective burning temperature is also more than a ‘Kacchi Bhatti’.

Simla Chuna is a type of stone lime found in Sardarshahar (hometown of Razak ji). It is made from ‘Dhandh ka Bhatta’, a kiln of Dhandh (a type of lime stone). It is a ‘Pakki Bhatti’. After extraction, it is used only after pisai in a chakki. Simla Chuna and Surkhi are used together. If Surkhi is not available, broken bricks are added into the chakki (the grinding instrument used with animals) and then both are ground well. It was used widely before, but now slowly work in lime has stopped.

In Bikaner (place in Rajasthan), limestones available are ‘kadak’ (type of limestone), from which ‘Darbari’ Chuna (local name of particular lime) is extracted. It is grinded and used but strength is lesser than ‘kali Chuna’. Darbari Chuna is burnt in ‘Pakki Bhatti’ (closed kiln, with a very high temperature of burning) and it takes a few days of preparation. As lime extractors are very few these days, it is difficult to source them.

Meetha Chuna, which is the major ingredient of P.O.P. It is these days are known as P.O.P itself locally, which is burnt and extracted from limestone in a ‘kachha’ Bhatti. Burning is done using gobari (dung cakes) and then pisai (grinding) is done before using it. Kacchi Bhatti is very easily done on site itself and lime can be used after overnight burning and cooling down.

Kali is extracted from pure white limestone, in a Pakki Bhatti (high temperature burning kiln).

‘Kalar’ Chuna from ‘Kaali Bhatti’ (kiln of Kalar). Both are used by cement companies.

From our studies and interactions with various master masons and lime artisans, we have understood that the grinding of lime helps in activating the lime, making it more powerful to bond. It was a traditional practice to grind lime in many places around India before use, which is one of the connecting links between various techniques from Rajasthan to Tamil Nadu.

3. As there are different types of Lime, does the way of giving Thappi differ?

Thappi is applied in the same way regardless of the type of Chuna. The proportion of Chuna and Surkhi varies if cracks are developing on a particular type.

4. Where have you seen Thappi is not applied?

Thappi is not needed in every kind of Chuna, it is not applied in Rajasthan where Meetha Chuna (type of lime in Rajasthan, a very pure form of lime) is used. Meetha Chuna is not used in exterior surfaces as it puffs up and flakes off but in interior plasters.

5. As you have also worked in Goa, what is your experience in working in Shell Lime?

Seep ka Chuna (Shell Lime) is a very pure and high-grade Lime, which is even used for all other uses of Chuna other than construction, like medicines. I have seen few artisans use shell lime in the later stages of ‘kada’ plaster (lime plaster with marble stone dust), where pure lime is needed. I haven’t seen anyone using it for masonry mortar or plastering. It is very pure and chikna (smooth) which makes it difficult to handle. The availability of Shell lime in Rajasthan is also very limited.

Shell lime is comparatively less strong than stone lime, as the impurities present in stone lime helps in better bonding of Surkhi and Lime. When shell lime is burnt in ‘Pakki Bhatti’ (high-temperature kiln) with charcoal and other substances to help burning are added to reduce the ‘chiknai’ (smoothness). These materials also help in better bonding.

6. What are the benefits of Thappi Plaster?

It is very cool and acts as a thermal barrier. Mitti (mud) is the best thermal barrier; Chuna is the second best. Stones also tend to be warmer than mud or lime. Exterior heat is never absorbed in a lime plastered home.

The strength of lime also increases in time (due to the carbonation of lime being exposed to air). But this is dependent on the ratio of lime and Surkhi. This is not like steel or concrete which dies out after time.

7. How is Thappi plaster water-proof?

As Thappi is given the surface cracks are repaired. Surkhi and Lime becomes a single entity and stop water from going inside, which makes the surface water-proof. If we apply a layer of Lohi or Araish (finishes above Thappi Plaster), it will further protect the surface, like how the skin is protected by clothes.

The pozzolanic reaction between lime and Surkhi makes it impermeable to water. Thappi makes the surface intact and repairs cracks, which prevents water from seeping inside. Read more about this in the interview with Dawood ji.

8. Is it essential to have multiple layers of plaster?

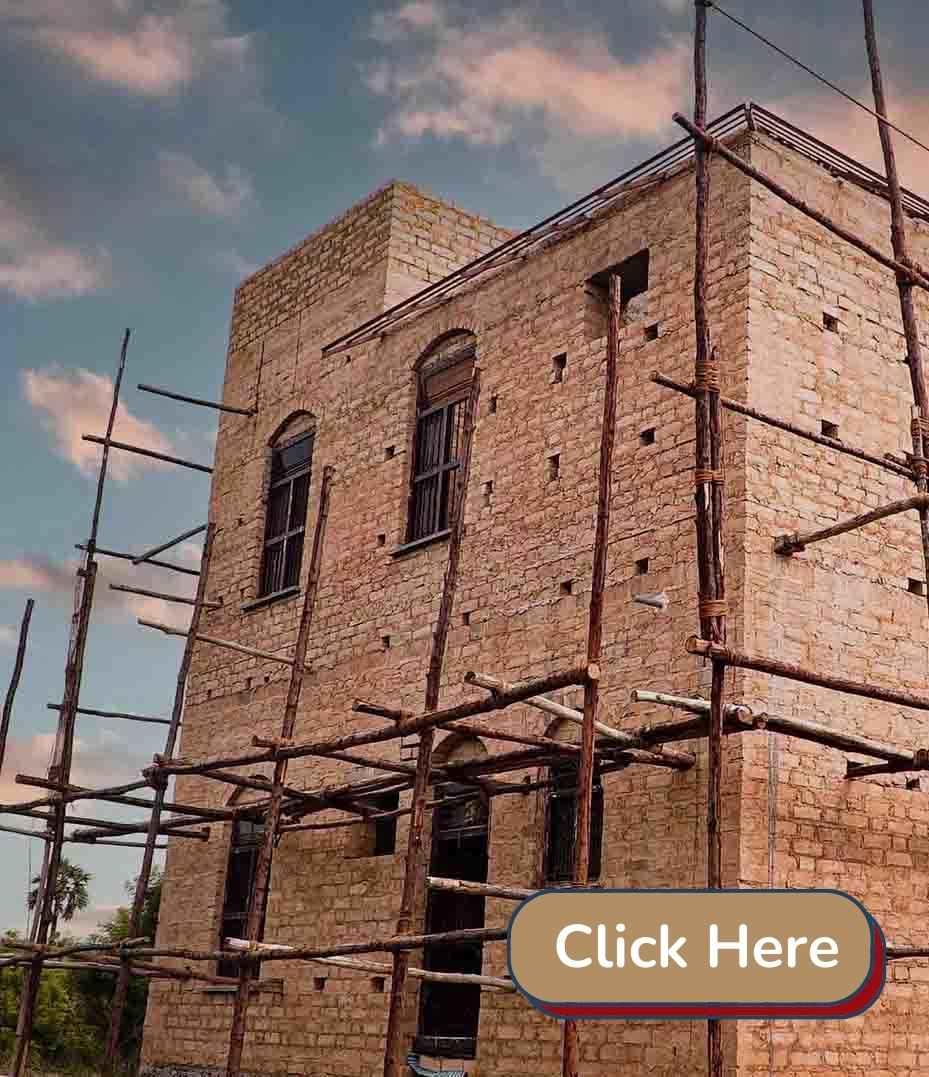

Only one coat of Thappi-plaster is enough to protect your walls. In Sardarshaher you will find many buildings with only 1st layer of plaster done on exteriors and standing for over 100 years.

Lohi and Araish are done in Interiors widely, where smooth finishes were preferred. Intricate finishes and paintings were also done on Lohi and Araish respectively. Only those who could afford to do them on exterior walls did it (like in Haveli) in olden times.

9. What are the different ways of doing Thappi?

Thappi is given in straight liner patterns (Thappi dena) as well as making round depressions (gadda lagana) on the surface.

10. What are the admixtures in this plaster?

Methi (fenugreek) seeds and Gud (Jaggery) is grinded, mixed in water and kept overnight and mixed with plaster to increase its strength and waterproofing qualities. Methi makes the mix more chikna (smooth). Gud pani (Jaggery mixed in water) is also added in for mortar also. People who worked on haveli and who have made them work have passed away, but Gud-paani wala haveli (buildings made with admixtures) still stands.

Moonj or Sarkanda (Saccharum bengalense) is used as a fibre in 1st coat of Thappi to decrease cracks and specific places where the strength of plaster is needed more, like roofing and flooring.

Belgiri ka ras (extract of Wood Apple) is also added while plastering complex joints and corners, bigger gaps or openings in the wall.

Lohi (2nd coat of fine sieved Surkhi-Lime) is done as a very thin layer, to a maximum thickness of two strings used for marking on-site (do suth motti). If a thicker layer of Lohi needs to be made, for intricate carving purposes, Methi-Gud pani is added.

11. How is a thicker layer of plaster added?

To add a thicker layer of 2nd coat, Lohi (fine sieved lime and Surkhi) along with admixtures you need to add a little quantity of pure lime in the form of Meetha Chuna (Sweet lime) or Seep ka Chuna (Shell Lime).

12. How much time do you slake lime before plastering?

Initially, when lime is put into water, heat is released (a few types like Simla Chuna doesn’t release heat when put inside the water). Once it is cooled down, you can start using the lime (in respect of Kali Chuna). There should not be any heat left within the lime before use.

13. How is Thappi plaster done on stone surfaces?

Initially, after masonry is over, a layer of Sareshi (base coat of Kali Chuna) is applied and left for at least two months. This is applied because stone and mortar joints tend to absorb water differently and subsequent plaster layers may develop cracks. So to even the surface, a base coat is applied. Once this layer sets in properly, 1st coat of Chuna – Surkhi (lime–baked mud) is applied and Thappi is given till it dries.

14. How Thappi plaster is used in terraces?

Thappi is used above flat roofs made of stone slabs to make the surface water-proof and plaster will act as a thermal barrier. Seeni (a by-product of Jute rope) is added for reinforcement in plaster. The surface is made further strong with kali ka paani (lime water).

15. What is the difference in using different types of lime in Thappi?

Various types of lime work differently in Thappi. If you are using Kali, the effort of giving Thappi is more than in Simla Chuna. It is because Thappi thodi pakad karti hai (Thappi keeps sticking to the lime) and has to be cleaned from time to time between work. This is because Kali is very smooth and Simla Chuna is rough.

Crack patterns in this plaster depend on the characteristic of the local lime and Soil used to make Surkhi. It also depends on how both are mixed, what are the admixtures used and all. Accordingly, proportions of both will vary and the right proportions needs to be identified with test patches.

This is only part 1 of the interview, part 2 will continue soon.

Biju Bhaskar & Akhil Shajan

This article is by Natural builder Biju Bhaskar & Akhil Shajan. This post is part of our People & Interviews series.

10 thoughts on “Interview: Thappi, a Marvel tool of Lime”

Namaste Surinder Bansal,

Happy to know your interest in heritage architecture. Restoring old Havelis and palaces is indeed a great art, and we are glad you enjoyed the article on the Thappi tool.

Great art in artitechure of restoring the haritage haveli andold palaces

Namaste Anand,

The second part isn’t published yet—we’ll let you know once it’s live. In the meantime, you might enjoy this related piece: https://thannal.com/understanding-lime-with-a-sprinkle-of-shayari-poem/

Can you please share link for the second part of this interview. i couldn’t find it.

Namaste Ali,

You can write a letter to thannalrootsgmail.com.

Hi iam looking to buy lime motor (mud chuna ) in rajasthan

Namaste Hitesh,

Please write to thannalroots<@>gmail.com

Looking for Rafiq Muwal’s number and office address would like to meet him.

Thanks Gautam Singh

Recently completed the ‘introduction to lime’ workshop organized by thannal in Rajasthan. An amazing experience interacting with the masters of lime in Rajasthan as well the enthusiastic and dedicated thannal team.

I am well on my way incorporating my newly acquired lime skills on my mud home near Bombay.

A big thank you to the people at thannal.