Speaking Natural Finishes series

If we draw insights from the composition of a human body and Natural Buildings, Plasters are the outermost skin of a building. They help to protect our buildings from various external entities like temperature and moisture (like the skin do). They impart an aesthetic language and dictate identity into space as it is the outermost layer visible. The use of mud plasters maintains the breathing quality of the wall made of natural materials, enhancing thermal comfort by keeping habitable temperatures inside. During summers, they remain cooler and during winters, the warmth of mud can be experienced.

The beauty of Indian plasters is that it utilises different natural derivatives from trees and herbs to increase the molecular strength, termite resistance and water repelling quality. Kitchen ingredients like Methi (fenugreek), Gur (jaggery), Kadukkai (Haritaki), Gooseberry, herbs like Aloe Vera, Cactus, Gums from Acacia (Arabic gum) and starch from rice, tapioca, wheat etc. are used. Animal derivatives like egg whites, animal hair, tallow, cow urine and cow dung are also crucial admixtures in plaster. Different types of mud and natural pigments like vegetable and mineral dyes helps in colouring walls through plasters. With the right recipe and simple preparation techniques, plasters can beautify the walls of any common man. The finishing layer can be of various textures depending on the technique used. Few exceptions like Thappi, Araish and Chettinad plasters requires skill and practice to execute and takes time to attain the elegant finish they offer.

Indian Plasters can be categorised into three for simple understanding.

Mud Plaster

Mud and Lime Plaster

Herbal Lime Plaster

Thappi and Araish Plaster

Chettinad Plaster

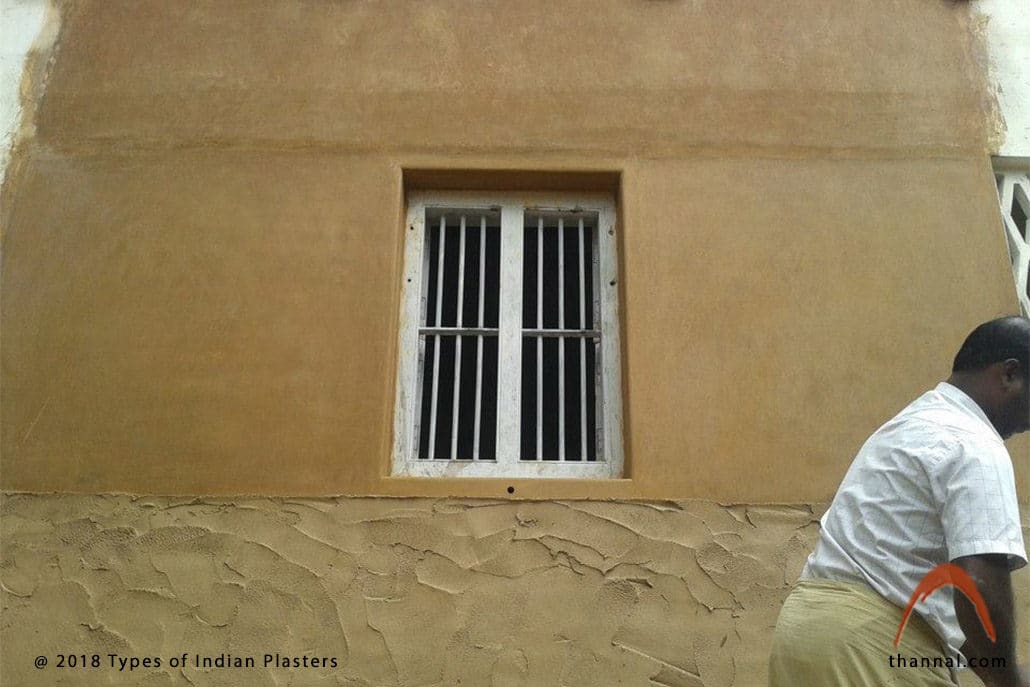

Mud Plaster

Mud plaster constitutes of Mud and Admixtures. The particles within mud are Clay (finest), Silt and Sand (coarse). In pure mud plaster, constituents of mud itself act as binder (clay in mud) and aggregate (sand in mud). In-case of clayey soil or sandy soil, clay content of mud is preferably kept between 12%-30%, by mixing mud types in required proportion. Fibres like rice husk is added to reduce cracks. Cow dung is also added for better binding, anti-septic and water repelling quality. Admixtures of starch from tapioca, tamarind seed helps in better bonding of particles, bark and leaves of Neem and Teak, Turmeric keeps termites away, Gums derived from Kulamavu tree (Persea macrantha), Acacia tree (Arabic Gum) can reduce the dusting in plasters. Various colours can be attained with mixing different types of soil and natural pigments. At last, multiple coats of linseed oil, coconut oil or neem oil is applied to water-proof the surface.

Links to plaster methods:

Videos:

Mud and Lime Plaster

Mud and Lime plaster constitutes of Lime, Mud and Admixtures. Lime is the binder here along with clay (in mud). Sand (in mud) in the primary aggregate. Fibres like rice husk is also added to balance the bonding within different components. Organic admixture like cow urine helps to boost bonding. Although lime keeps termites away, herbal termite repelling solutions will provide an extra protection in moist climatic conditions. Natural polymers and starch can also be added as per requirement to increase the stability of plaster after testing with different mud samples. Lime with time sets due to carbonation and makes a plaster layer as tough and solid as lime stone.

Further reading:

Do you want to study Natural Building Online ?

Herbal Lime Plaster

It consists of Lime, Surkhi and Admixtures. Lime is the binder here, Surkhi is the aggregate. Surkhi is burnt mud, derived from broken terracotta tiles or bricks or just burning mud lumps. Surkhi bonds well with Lime as moisture absorbed by the burnt mud facilitate settling of Lime. This is a major benefit of using Surkhi over river sand, which is facing a shortage in availability due to heavy demand. Herbal mixes like the Kadukkai-Jaggery mix initiate molasses reaction within and increase the bonding between particles. Natural Polymers derived from Cactus, Aloe Vera can enhance the sticking of particles to each other.

This plaster shows resistance to erode with water splashing on it after settling of lime. Excellent water-proofing qualities make it perfect for Water tanks and bathrooms.

Read more:

Thappi and Araish Plaster

Thappi is the tool used for tapping or beating the lime after application to facilitate setting of lime. Thappi plaster technique is native to Rajasthan and other parts of India. The key ingredients are Lime (binder) and Surkhi (aggregate). Base layer of Surkhi and Lime is applied and Thappi is used to tap on the surface. This is repeating until you hear a ringing sound on tapping, after 3-4 days of Thappi in regular intervals. Cracks formed during drying get repaired in this Thappi process.

Above the first layer, wide range of finishes are possible.

- Lohi is the simple and quick finish, involving fine sieved Surkhi and Lime.

- Araish is the detailed and intricate finish, done in layer by layer. It uses marble dust, lime (slaked for long periods) and various natural pigments. It is applied with care and precision and is an art work mastered through practice.

Natural Gums and Polymers derived from Methi (fenugreek), Gur (jaggery) and Gguggul (Commiphora wightii) are used in various stages of plastering. This helps in attaining water-proof surfaces like Tadelakt plaster. This method gets rid of any fear of mud walls getting in contact with water. The procedure of applying plaster must be carried out with precise judgement maintaining work quality. Thannal has attempted to revive this technique through master mason Dawood ji’s work of Thappi Plaster on exposed walls and water tanks and initiated a workshop to help more people learn this and spread it.

Further reading:

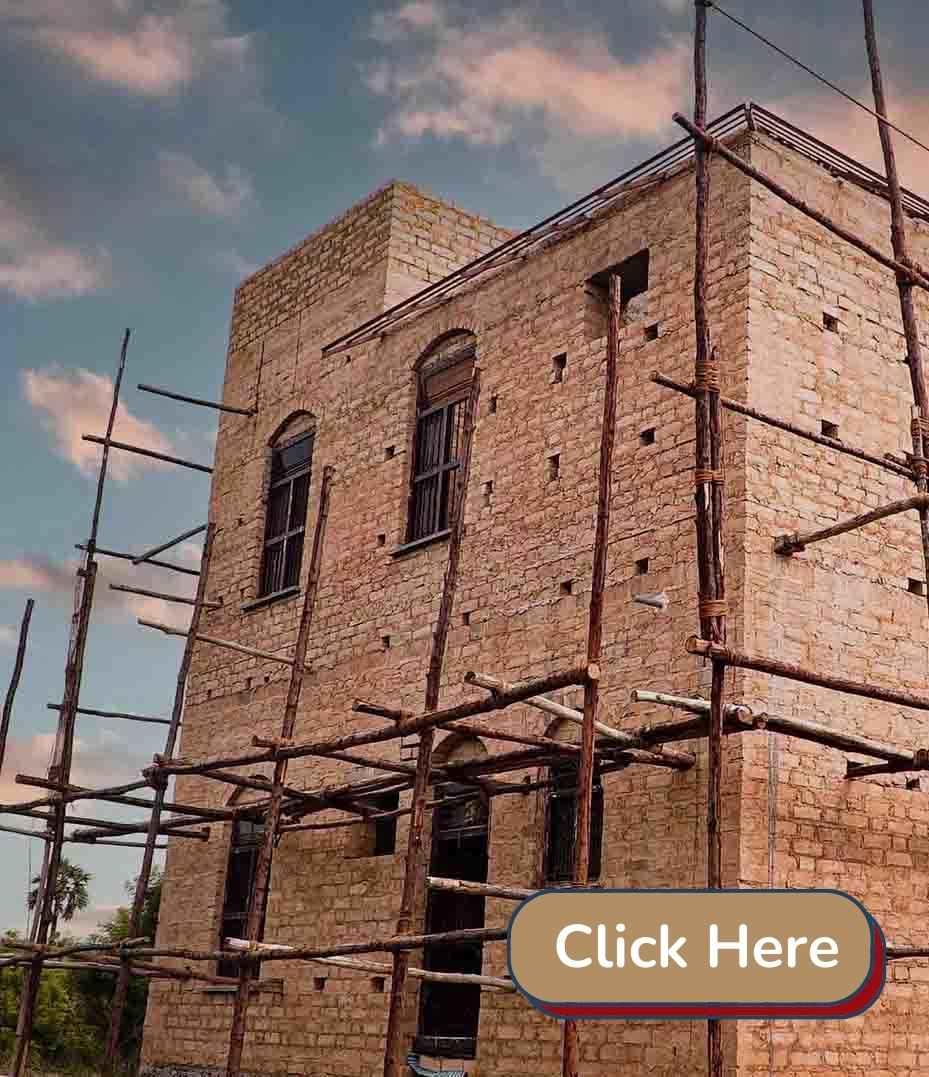

Chettinad Plaster

Lime plastering technique native to Chettinad, Tamil Nadu. Extensively seen in the 18th century mansions of Nattukottai Chettiars, a wealthy trading community. Major ingredients are Stone lime, Shell lime (binders) and River sand (aggregate). stone powder (quartz) is also used. Admixtures like egg-whites and vajjram (tallow) is also added. It is known for soft texture, bright colour and reflective glazed surfaces. This involves rubbing the surface with stone by craftsman to attain a very smooth finish and this requires no other treatment methods.

Videos:

Biju Bhaskar & Akhil Shajan

This article is by Natural builder Biju Bhaskar & Akhil Shajan.

This post is part of our Natural Finishes series.

8 thoughts on “Types of Indian Plaster part 1”

Namaste Oscar,

Hello from India, and thank you for reaching out with your query all the way from Peru! It’s wonderful to hear about your interest in incorporating natural elements like neem and turmeric into earth building techniques.

Regarding your question, various parts of the neem tree can be used in their fresh form, including leaves, seeds, and bark. Each part has its unique properties and can contribute differently to the plaster or mud floors. As for turmeric, it is the dried rhizome of the turmeric plant that is typically used. This rhizome is ground into a powder, which can then be incorporated into building materials.

To gain a more comprehensive understanding of how these and other natural admixtures can be used in construction, you might find our self-paced online course on admixtures for natural building construction quite insightful. The course covers a range of natural additives and their applications in detail. You can check out the course here: Admixtures for Natural Building Construction – Part 1.

Hello from Peru! Could you please explain a little about how to use neem and turmeric as additives in plaster and in mud floors? We would like to know which parts are used, leaves or rhizome, should they be fresh or dried, fermented, extracted…? Your shared knowledge is much appreciated since the use of plants is not common practice here in local traditional earth building techniques. Thank you in advance.

Namaste Shan,

Shell lime is widely used for plastering.

What about the plaster made of crushed shells from the sea? The old administrative buildings in Calcutta we’re built using shell plaster to shimmer in sunlight and moonlight . This mixture may have been called “chunum”?

How do we plaster a pond to store water or grow water plants

நன்றி ஐயா

அருமையான விளக்கங்கள் ஐயா, தங்களின் vணி தொடர வாழ்த்துக்கள்… மரபு கட்டட கலையை அனைவரும் பயன் Uடுத்தி நலம் ெபறட்டும், நன்றி

I am I Busi ess of IRANIAN Gypsum Plaster and wants to go for Further Improvements in the same !