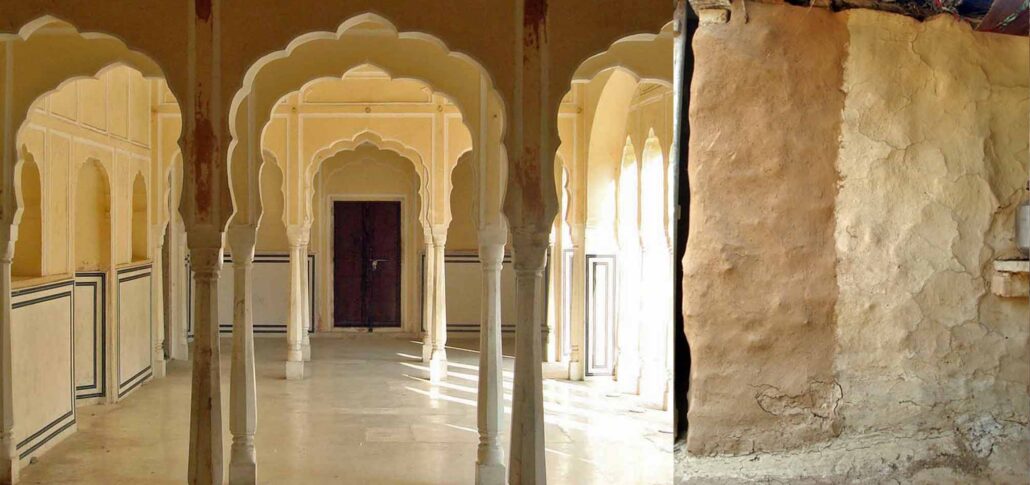

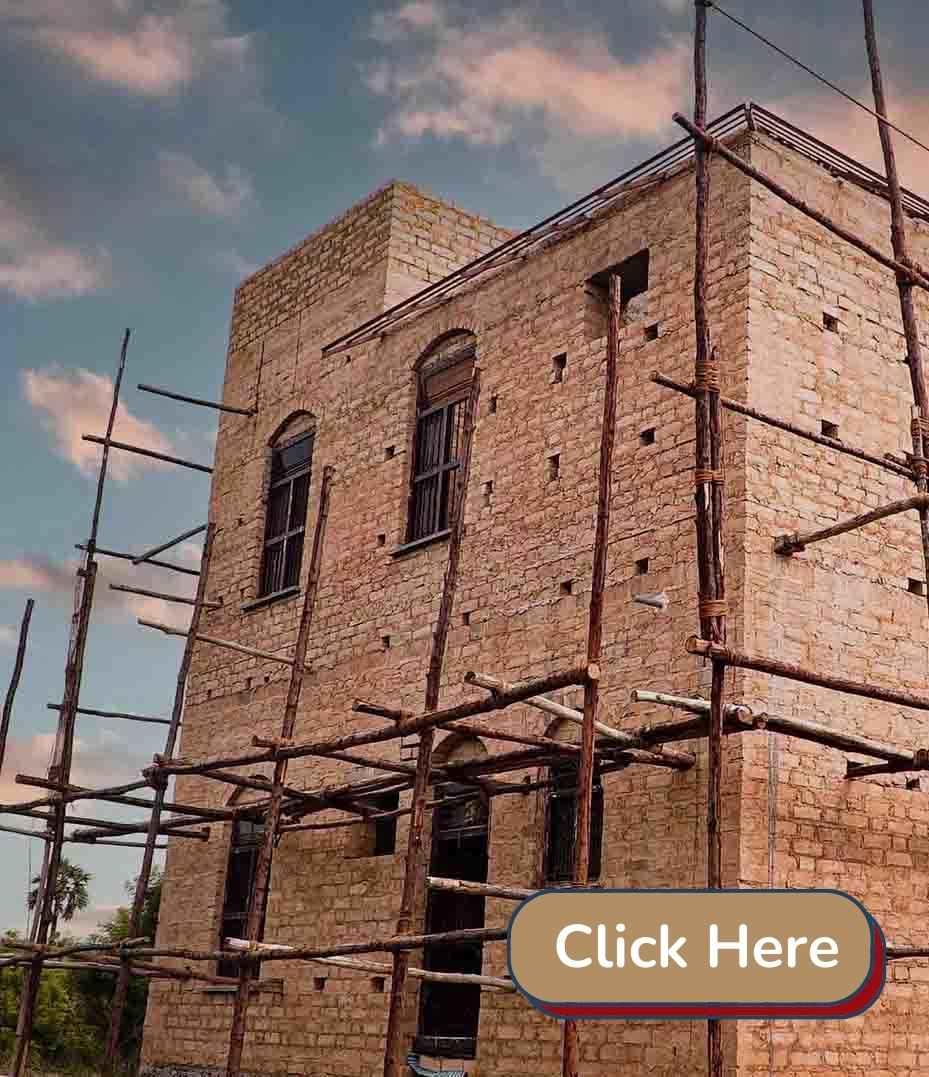

In Rajasthan you can find both the limits, the extravagant finishes of the palaces and the humble plasters of the villages, both made using natural materials. The finishes found in the palaces of Jaipur are more elaborate and expensive. These have been skillfully done, are time consuming and last for a very long time. Ranging from the smooth araish finish to a variety of colours of lime paint, these finishes offer a wide range of possibilities. On the contrary, the modest plasters of the villages here are generally easy to source locally and simpler to use and reuse.

Araish: This fascinating finish is one seamless reflective surface enticing not just the eyes but your sense of touch to feel the smoothness. This tadelakt of India is made with ingredients from the kiln as well as the kitchen. Applied gently with care and precision these plasters are a work of art. Before you obtain the final look, there are layers of work that go below the silky exterior. There are different coats of plaster underneath, each with a different grade and function.

Surkhi– This layer over the stone walls is the base coat made using slaked lime, brick powder, gogol (incense), natural gum, fenugreek seeds water, jaggery,and kesule ke phul. These ingredients are mixed and kept for months to ferment before application.

Zikki plaster– made using equal quantity of slaked lime and marble dust, this plaster is the next layer which is the base for the araish finish.

Finishing layer- lime milk from six months matured putty is taken and added with curd and kept to ferment for six more months. This paste is applied over the base and then polished using a special rounded stone till a glossy finish is attained.

Coloured lime finish: This is done similar to araish, only difference is that a pigment is added to achieve the desired colours. The very common yellow paint is attained by mixing yellow mud in the lime mix and applied with a brush in two coats.

Mud Plaster– Chikni mitti or clayey soil 3 parts from the banks of the ponds is mixed with 1 part fresh dung obtained from the traditional breed of cow. These two are kneaded and water is added to attain the right consistency for application. This is hand applied in thick layers on stone walls or mud walls to create interesting patterns. These walls may be re plastered as and when required.

Lime waste Plasters– Two parts of river sand is added to one part of the powdered lime waste and mixed well. To enhance the strength and make it more workable, overnight soaked methi seed water and jaggery water is added to this mix which is then used to plaster the walls.

Musharaff Hebballi

This article is by Natural builder Musharaff Hebballi. This post is part of our Natural finishes series series,.

5 thoughts on “Plasters of Rajasthan”

Namaste Kruttika,

You can write a letter to thannalroots<@>gmail.com. Yes it’s waterproof. You can learn Surkhifrom our online course library – https://course.thannal.com/s/store/courses/Materials

Hi… it’s so wonderful that you can indulge your passion! I have bought a small piece of land and wanted to do tadelakt plaster for my bathroom but don’t know how to get materials, technique etc. This Rajasthani Surakhi is also waterproof? Where can I learn the technique?

Namaste Bobby,

Kindly write to thannalroots<@>gmail.com

Hi I am looking for artisans for my project in goa

I saw this type of plaster finish while on a tour of Rajasthan just before the COVID pandemic and decided to copy it at home in the UK during a lockdown in our 450 year old house as some internal walls needed re-plastering in lime.

The process is fun to do but does take some time, especially the final polishing with a flat stone, however the result is very tactile and hard and I am really pleased with the result. I have done a lot of lime plastering before, but not tried polished lime before.

For my next Project I need to do a larger wall and will need to have some joins as it will be to large to do in one event before it dries and I am researching how to get seamless joins.