Indian Lime Revival – series 1

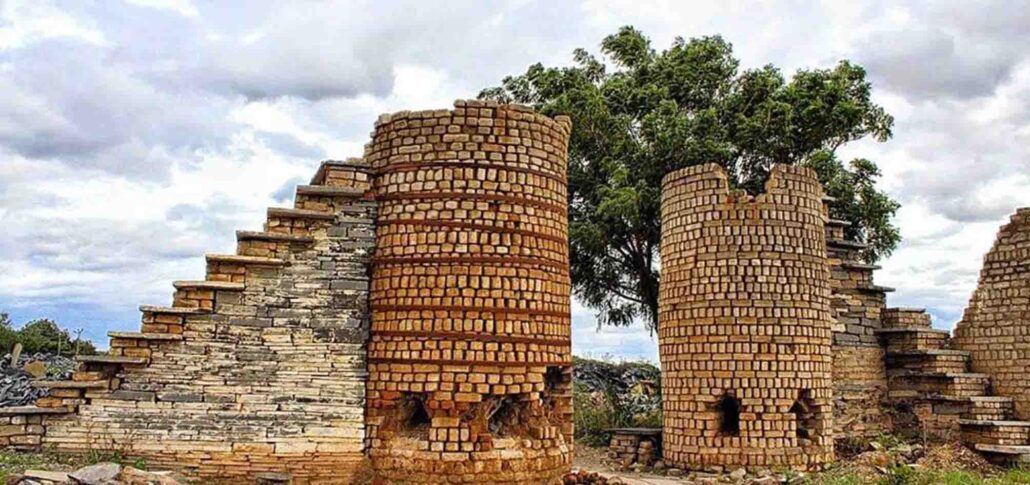

It’s a temple, right? The smoke must be from the ‘Aarti’ sessions, but wait why is it continuous? Nonstop ‘Aarti’ sessions? Kaunsa bagawan hai andhar ?(whose temple is it ?)

It’s a small ancient house, right? The smoke must be from the ‘choola’, but wait why is it continuous? They are probably cooking for many people, but how will so many fit in such a small house? Kitne compartments honge ismein..?(How many compartments it might have..?)

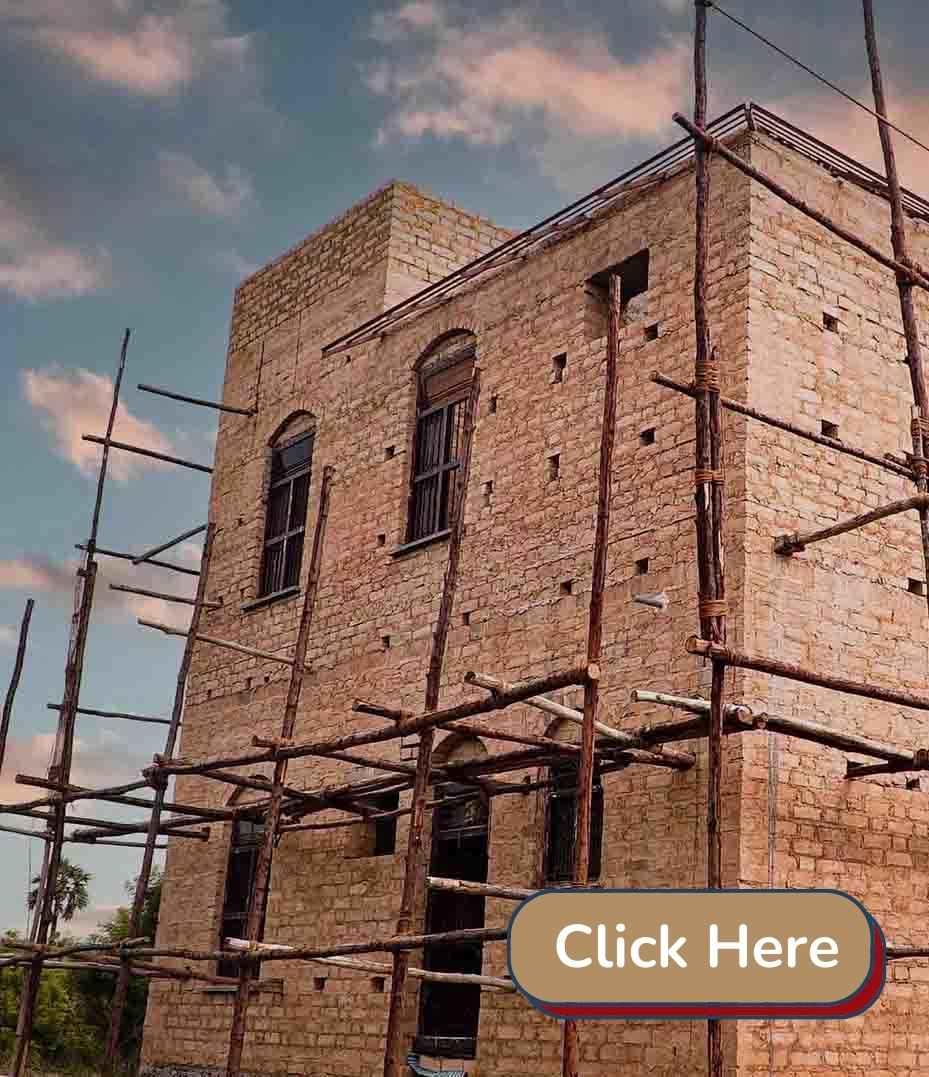

The above could be some of the perceptions of many among us at the first glance of the incredible ‘Lime kilns’, they are the Lime kilns that have been tirelessly supplying us the best lime through generations. But the role of lime has changed, (from being the crucial material in the construction as mortar to just being an external pre-coating), we no more see it in its true form, its strength (the very Lime kilns give us an account of it, standing firm, despite of being exposed to harsh climatic conditions). Not saying it’s lost, but it was our way of life with Lime kilns, there was a time where it was accessible to everyone, it wasn’t a “ mass production” but the lime kilns were everywhere and sometimes also in the backyards of individual homes. The glory isn’t lost, we can reintroduce them back into our lives into our homes, in this age of global warming they could be the saviours. It’s time we look back for a better future.

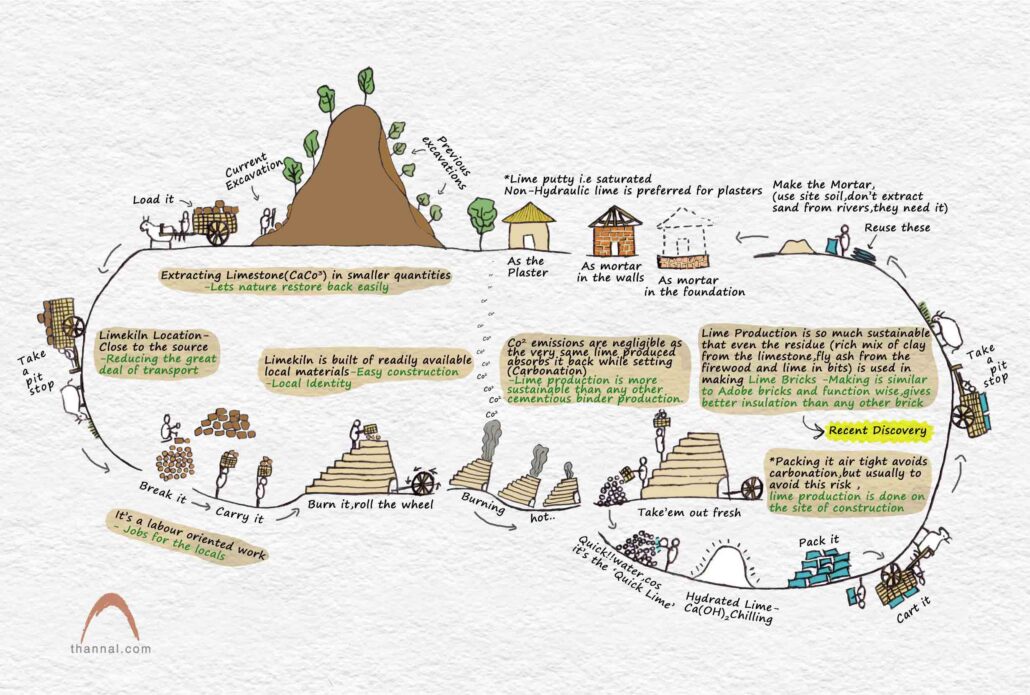

“Namma Lime Kilns” Lime stone cycle by Dheeraj Reddy – Namma means ‘Ours’

The production of lime is totally sustainable, it’s a cycle of life in a way, where the nature is not abused but embraced. The production involves the following steps,

i ) Lime stone Excavation (done from the nearby quarries in small quantities without the use of ‘explosives’)

ii ) Burning Limestone in the Lime kiln(yes the burning or calcining results in CO2 emissions but are negligible when compared to that of a cement production unit, also lime plaster during the setting period absorbs back the atmospheric CO2 )

iii) Hydration of Lime (Involves very less input of water and is the last step before the resultant powdered lime is packed and sent)

Thus lime production though a little laborious (because there are less “’machines” involved), the result is something the Lime maker is proud of, fine quality lime. The design of the Lime kilns doesn’t just abide by the factor of fuel efficiency, but also as per the comfort of the people involved and aesthetics that reflect the local culture, the following Lime kilns will relish you with their vernacularity ( in both material and design, adobe bricks, mud plaster and stone are most commonly used materials)

Find contacts of functional Lime Kilns in the Thannal Material Directory (which will be updated soon) in this link.

Below are the FB photos were taken by Biju anna in his travels and researches in Indian villages talking to older people who worked with lime.

Press the Facebook blue logo to see all photos in the album

Dheeraj Annapureddy

This article is by Natural builder Dheeraj Annapureddy. This post is part of our Ageless village series,.

4 thoughts on “Path way to Lime Kilns”

Namaste Rashmi,

Kindly write a letter to thannalroots(@)gmail.com

Regards – Thannal team

Request some address of lime kilns up north _ Rajasthan and Gujarat or even Karnataka or Mahatashtra as we are not getting any reliable source for procuring lime to start our project in Goa.

Very well written Dheeraj! Bahut acchhe! 🙂

And the illustration is also very good..

This is great! Nice to see that some kilns are still alive. 🙂