Natural building techniques – Series 1

Introduction

Natural Building includes a variety of wall construction techniques that are typically drawn from old traditional methods of shelter making. These techniques differ from place to place, depending on the availability of materials and their response to moderate and extreme climates. It emphasizes the use of locally available materials, practices which sensitive towards mother earth. They blend with the natural and cultural surroundings and focus on skills and resources that are locally sourced and economically viable. These walls create micro-climates inside them to provide high thermal comfort levels, thus a healing effect on one’s mind, soul and health. In addition to it, the earthen wall also displays a dramatic variation in terms of textures and colours.

Note: Each wall system specified below are purely done in Mud, stabilized with Lime and natural Admixtures. Sustainable practices involve eco-friendly, pure materials used and affordability, by being on par or less with the conventional construction costs. The use of Cement is strictly avoided because it harms the quality of such walls

Cob

Usually, when people say “Mann Veedu” (Mud house) they are unknowingly referring to a cob house. We can locate it in every part of India and around the world.

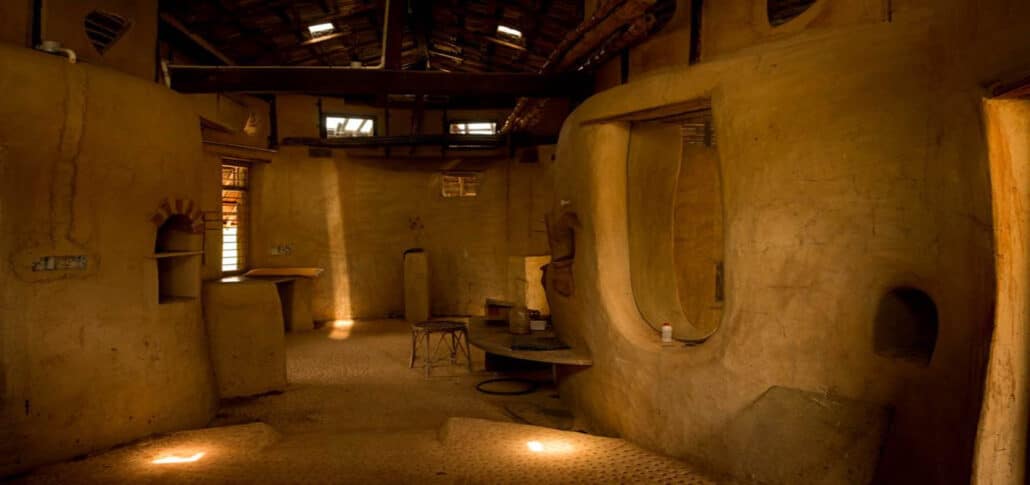

Cob is a homogenous blend of sand, silt, clay mixed with fibres. In the Indian way of cob construction, Herbal mixes like Kadukkai-jiggery and neem-turmeric are added to the mix in order to protect them from termites and enhance their strength thus prolonging their life span. These structures can are highly resistant to earthquakes and have the exceptional thermal mass trait.

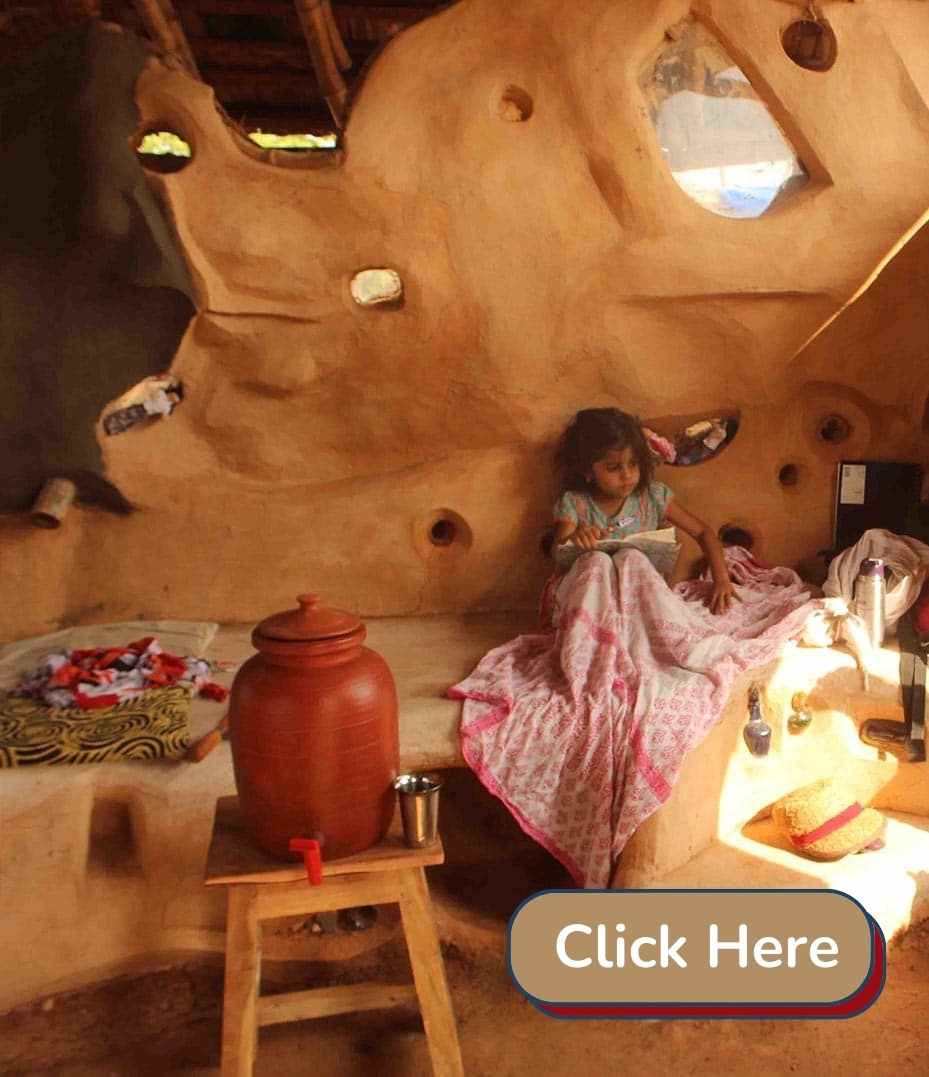

Cob lumps are placed and hand sculpted to build a structure. It is fabricated in layers and relatively has thicker walls, it gives the builder a tremendous amount of freedom to explore varied forms and shapes.

- Monolithic structure

- Load-bearing walls

- More water used

- Easy to sculpt on top readily

Photo FB album of hand sculpting cob building: Making of Singing dervish studio

Video of the making of a cob home: Erikarai Cob home

Book on Cob construction: Natural Building Books Part-1

Wattle and daub

Wattle and daub is a natural construction technique that has been used by rural communities of different cultures around the world.

There are two parts to this technique: The wattle is essentially a wood or bamboo frame structure that has woven pieces of lattice tied to either side of the wood frame wall. The daub is an earthen mix, similar to cob but more damped. It is used to fill in the hollow spaces between the horizontal wattles and to plaster the wall. The amount of earthen material needed for a wattle and daub home is significantly low. The construction usually can be completed more quickly and efficiently. A wattle and daub home can be built if you have plentiful sources of tree branches, twigs, clay soil, and water and will last for decades as long as you keep the walls somewhat protected from the rain.

- Monolithic

- Non-load bearing

- More water used

- Easy to sculpt on top readily

Photo FB Album of wattle and daub building: Wattle & Daub/Cob Organic Farm Cottage

Video of making of wattle and daub cottage: Weaving walls, a wattle & daub cottage

Book on wattle and daub construction: WEAVING WALLS

Rammed Earth

The rammed earth construction technique generally possesses high durability and has been used for thousands of years. There is a handful of buildings still standing that are centuries old.

I.e. Great Wall of China.

These walls are constructed by ramming a mixture of aggregates, including gravel, sand, silt and a small amount of clay, into place between flat panels called formwork and compressing it in layers. They are very strong in compression and can be used for multi-storey construction. If stabilized with lime, the walls can be left without plastering as well. Different soil types can be layered to obtain varied colours and textures for aesthetics.

- Monolithic

- Load-bearing

- Less water used

Photo Album of Rammed earth buildings: Small rammed earth designers home

Video of the making of Rammed Earth walls: Rammed Earth Basics

Book on Rammed earth construction: Directory of monolithic wall systems

Do you want to study Natural Building Online ?

Adobe

The use of adobe bricks can be tracked down from the earliest known civilization known to man to the recent ongoing excavation at Keezhadi, Tamil Nadu.

Adobes translates to sun-dried mud brick. It is composed of sand, silt, clay and fibres, similar to that of cob mix. This final concoction is poured into a frame to form a brick shape. Once the shape is cast, the frame is removed and the bricks are left to sun-dry. It can be cast in varied shapes, sizes and forms and used just like conventional bricks. Structurally it is substantial and provides good thermal mass to the structure.

- Masonry

- Load-bearing

- More water used

- Can sculpt on top

Photo Album of Adobe Seed bank: Kerala adobe seed bank

Video of making of Adobe: THE ARCH OF ADONIS

Book on wattle and daub construction: The Owner-Built Adobe House

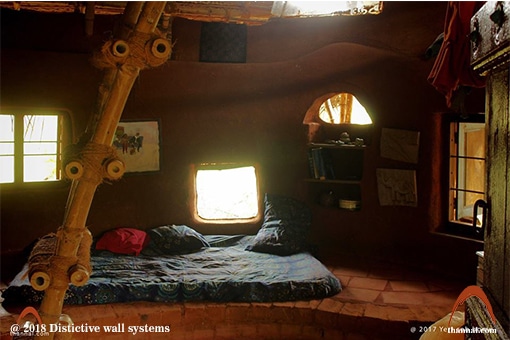

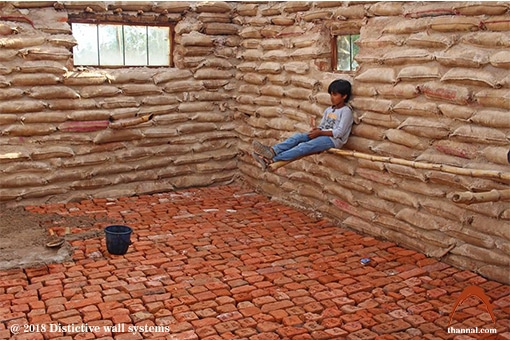

Earthbag (Superadobe)

Earthbag construction is both a new and old construction technique. It has long been used extensively for creating a barrier or for flood control. However, it has come into the practice to build permanent structures in recent times.

Jute Sacks are filled with moistened earth that is set on the wall and compressed using a hand tamper.

The traditional jute bags will eventually degrade, thus it is essential to plaster the structure. Since the walls are so substantial, they resist all kinds of severe weather and also stand up to natural calamities such as earthquakes and floods. They can be erected simply and quickly with readily available components, for very little money.

- Can be both Monolithic and Masonry

- Load bearing structure

- Less water used

Photo Album of Earthbag Studio: Earthbag home in Tiruvannamalai

Video of the making of Earthbag studio: 1.1 M views video of Earthbag Home

Book on Earthbag construction: Building With Earth: A Guide to Flexible-Form Earthbag Construction

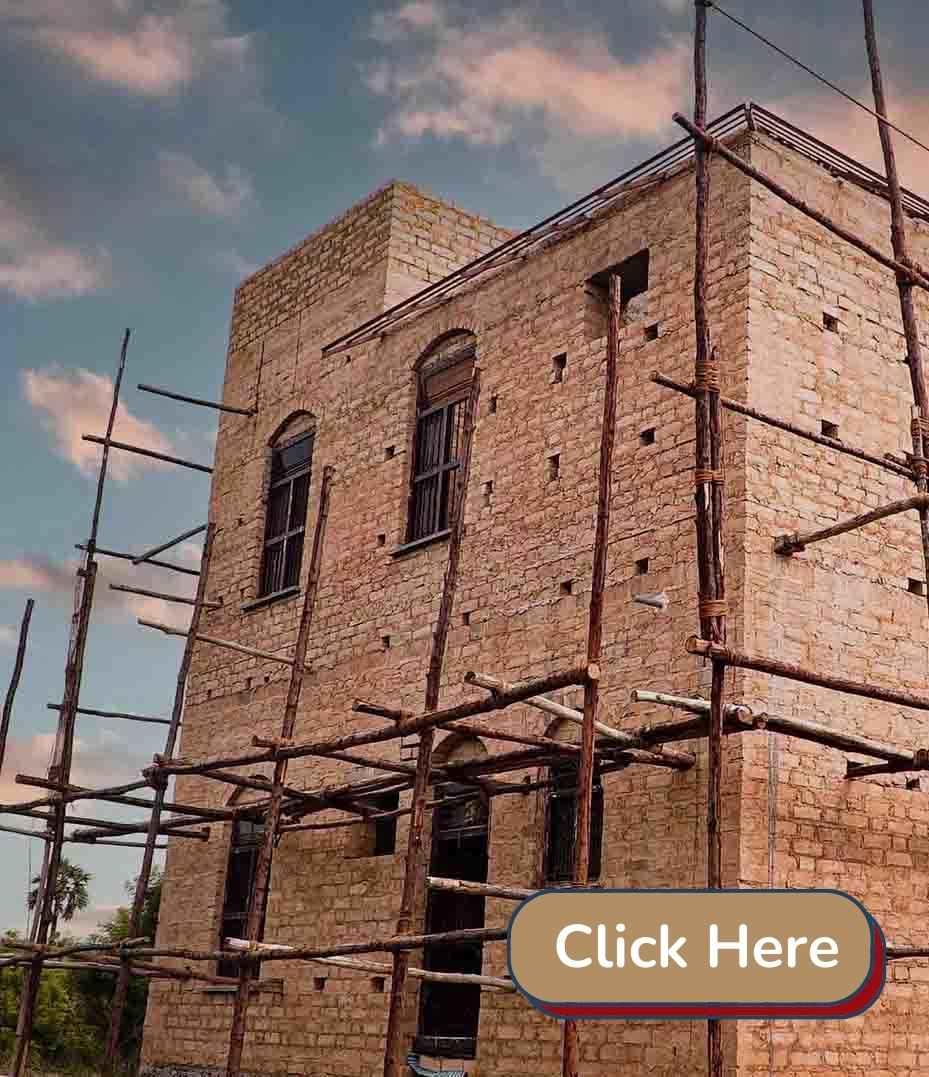

CSMB

A compressed Mud block (CMB), is made primarily from damp soil compressed at high pressure to form building brick-like blocks. A mechanical press is used to form mud blocks out of an appropriate mix of fairly dry inorganic subsoil, non-expansive clay and aggregate. If the blocks are stabilized with lime they are called compressed stabilized earth blocks (CSMB). Stabilizing the blocks with lime makes them strong, stable and most importantly water-resistant and long-lasting. The duration that the blocks consume for drying after compressing is very minimal. On-site materials can be used very efficiently thus reducing the cost of construction and increasing efficiency and sustainability.

- Masonry

- Load-bearing

- Less water used

Photo Album of CSMB water tank: CSMB water tank

Video: Coming soon

Read Article: CSMB and Cob wall 2 story home in Kerala

6 thoughts on “Earthen Wall Systems”

Namaste Rajendra,

Thank you for liking our article! We have created an online archive of natural building, which you can find here: https://course.thannal.com/s/store. Please take a look and let us know if you have any questions or comments!

I was searching for the basic content on construction of mud walls which includes details like type, material used etc all these details were available at single place thanks for blog

great to learn at one place

Really very nice to see this we wanted to study this, going there for class

Hurrah! In the end I got a blog from where I be able to truly take helpful facts regarding my study and knowledge.

Thanks fοr finally talкing about >Earthen Wall Systems <Liked it!