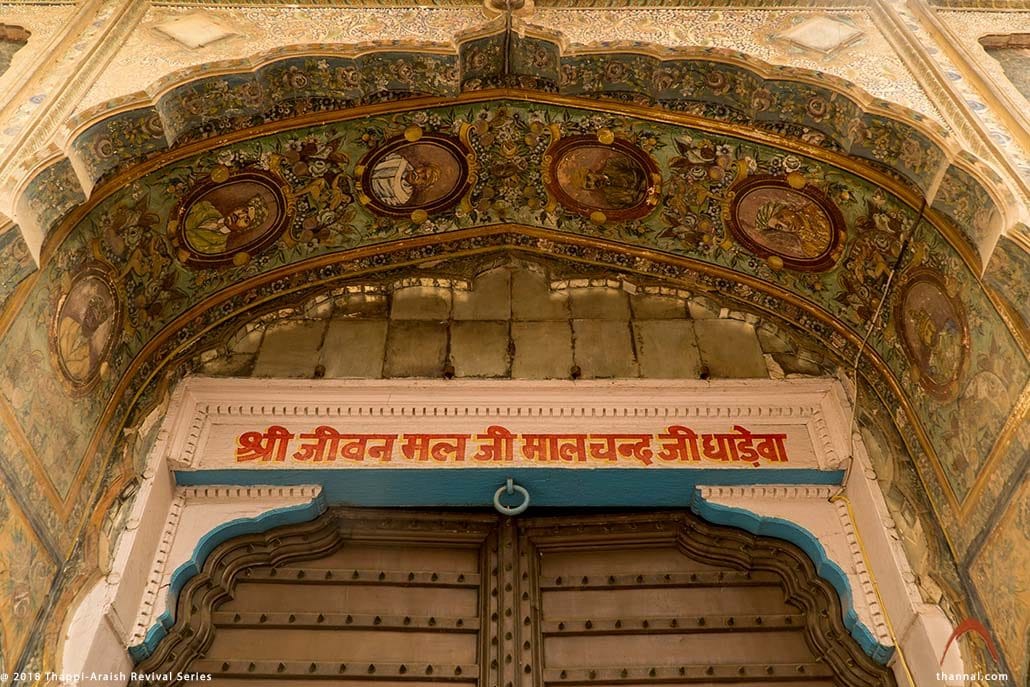

(Revival Series: Thappi-Araish Lime Plaster, Rajasthan)

Biju Bhaskar in his research and journey of Thappi Lime Plaster across Rajasthan met many artisans in their 70s and 80s, who have worked a major part of their life in these traditional artforms. During one of his journeys, he could meet & interview Yusuf ‘Painter’ of Sardarshahar, renowned for his skills in traditional paintings found in the Havelis in the city. He has been accolated for his contributions to ‘Prakritik Chitrakala’ (traditional painting) by the Government of Rajasthan. A master in using traditional natural colours on Lime Plaster, namely, Araish (Kada) Plaster, seen widely in Rajasthan, he is now looking after the mural work of a Haveli done by his sons in the same city. This art form is fading due to a lack of available materials, skilled workers and patronage. Thannal is exploring possibilities on how to Revive this traditional plaster of Araish and Thappi and bring it back to contemporary architecture and Natural Buildings.

A dialogue with Yusuf ji on his work and experience on different kinds of Natural colours used on Lime Plaster.

1. When did you start your work?

I belong to a family of traditional mural artists. Before, if someone needed to paint or have colours in their Haveli, mural artists were given the job of making murals over the lime plasters. I have started my work as a mason in 1962. Before that, we used to be assistants with family elders, who were painters. After three years, in 1965, I started with painting, on canvas and walls.

2. What are the major types of colours available initially?

There were two primary sources of colours, from Mitti (soil) and Pathar (stone).

3. How was your experience with different colours in your work till now?

I had seen my father and grandfather using colours derived from stone when I was young. I used to assist them in my childhood before I started to work. But by the time I began to work, colours manufactured by companies had been available in the market, and people began to use them. It was known as ‘Persian colour’ in the local market of Sardarshahar, Rajasthan. I have used both natural colours and company made colours during my experience of over 50 years. I used to paint on canvas using watercolours and upon the availability of work, worked as a mural painter in Haveli also.

4. What is the ‘Stone’ colour?

Colours extracted from stones (category: mineral dyes). One way to extract colour from stone is through the burning stone in a kiln, after which it is crushing and grinding with adding little water. Another way is to skip the kiln burning, crushing and grinding with water. It has to be done consistently for some time to extract colour intensely. Burning reduces the weight significantly of the colour, so if you procure it after burning, it will be lighter than ‘Mitti’ colour.

5. Do you know anyone in Sardarshahar who can extract colour through a kiln process?

No, not presently. There used to be people during the times of my father who used to do it. As the demand diminished, people who used to do this shifted to other jobs to earn a livelihood.

6. What is the current scenario of Stone colours?

It is challenging to source them, as the demand is deficient. Few old shops who are aware of it can order but availability remains uncertain. I believe a few artisans working in making ‘Chini Mitti’ (porcelain) will still continue to use these stone colours, on the surface before its burnt and made permanent. The use of such colours in buildings has diminished. I am presently working with distemper and normal company made colours.

7. What is ‘Mitti’ colour?

‘Mitti’ colour is made from soil, it is available in various shades of red, yellow, green. It was later manufactured by ‘Germany’ company, available in options like ‘Germany peela’ (yellow), ‘Germany Lal’ (red) etc. Buying the right ‘Germany’ colour is difficult as shopkeepers these days are confused between ‘Germany’ and ‘Cement’ colours. ‘Cement’ colours are made of chemicals. They are used as pigments in mortar. I am not sure if they are made from natural sources. But you can always differentiate between both, by analysing their weight. ‘Mitti’ colours will have less density, which means if you by the same quantity (in weight) of both, Mitti colour can be used to cover more area (than ‘cement’ colour). For blue colour, ‘Neel’ (Indigo) was used which is not made from Mitti.

8. How to judge the authenticity of ‘Mitti’ & ‘Germany’ colour?

Authentic ’Mitti’ and ‘Germany’ colours will have more weight than stone colour, but will have even more weight if mixed with adulterants. The working space or spread of colour also reduces substantially if mixed with adulterants.

9. Have you worked on colours derived from plants?

Yes, I have extracted colour from ‘Kesule ka phule’ (Flame of the forest) and used it for colouring. It is easily available on market in ‘dried form’. It is soaked in water overnight and then the extract is filtered and used in Kali (lime). The intensity of colour depends on how much quantity of extract you use.

Another source is ‘Lakh Dana’ (Seedlac or lac) which is generally used for polishing wood. It is grinded, soaked in ‘Kali’ (Lime) for overnight and filtered before using the colour. It was a long time before I had used these colours.

10. How do you use the colour other than adding colour into Lime?

In earlier days, a painter used to derive the colour needed, from ‘gatiya matti’ (lumps of mud). ‘Matti’ is grinded and then filtered. Then ‘sukka’(dry) colour is added to this filter. Milk is also added to make this mix more ‘chikna’ (smooth). Then it is used above ‘Kali’ (lime). If required, ‘goond pani’ (Natural Gums) are also added to make it more gluey. Then it is applied on top of ‘Kada’ or ‘Araish’ plaster (lime plasters using marble dust).

11. Why is milk used?

Milk is used to mix the ‘dry’ colour. Water is added later to make it into workable consistency. Such colours won’t come off when stains are wiped off with a wet cloth. They tend to retain their finish, even after years pass by. I used to use dry colours, manufactured by ‘Shalimar’ (name of company). As plastic colours grew in demand, ‘Shalimar’ stopped production and these kinds of colours faded away from ‘Bazaar’ (market).

12. What is the difference you feel between the old and new colours?

The ‘plastic’ colours which come these days aren’t stain-proof like natural colours. They tend to lose their ability to retain the finish for long. On the other hand, Natural colours applied correctly can be still seen intact on the exterior walls after being exposed to sun and rain for decades. If you compare the expenses also, ‘plastic’ colours are very expensive. The colours derived from nature are much more affordable and last much longer if applied using the right technique.

13. Can we see any of the older work done by you?

I have done many works in Havelis in Sardarshahar, but many are closed as the owner’s doesn’t reside here. They are not maintained well also. You can see a few works which is done outside by my forefathers. Work on the outside walls are in bad condition, either covered with posters or repainted with modern paints. People don’t know the value of this work, so they are less bothered to conserve them.

14. Will you be interested in working in an older style, given a chance now?

It is tough for me to work due to old age, but my children in the field can work, after learning the older techniques from me.

Biju Bhaskar & Akhil Shajan

This article is by Natural builder Biju Bhaskar & Akhil Shajan. This post is part of ourPeople & Interviews series.